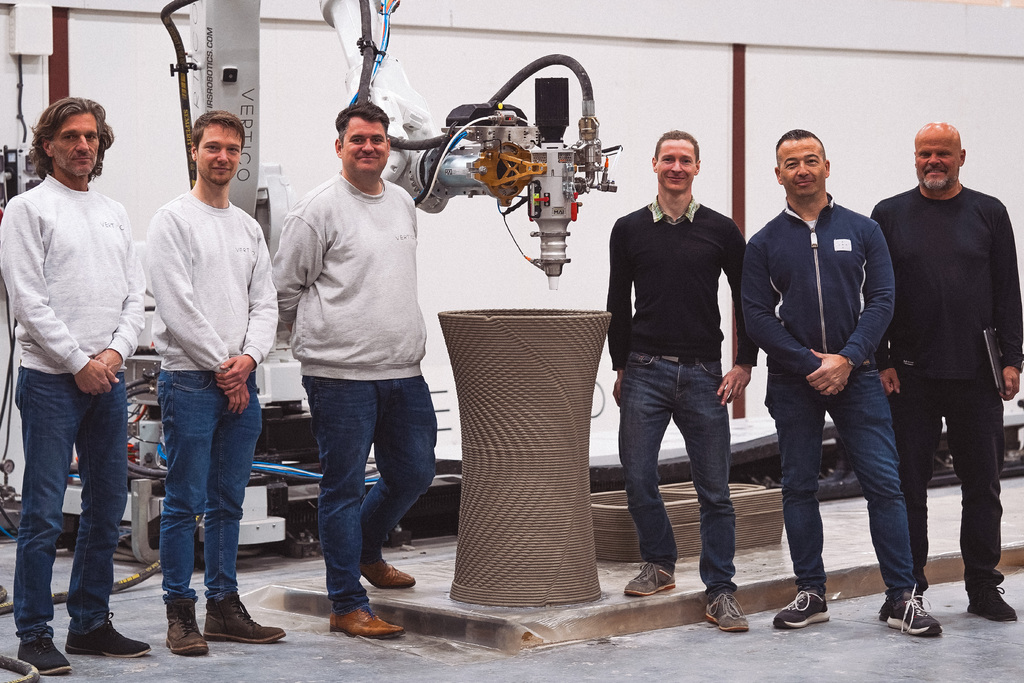

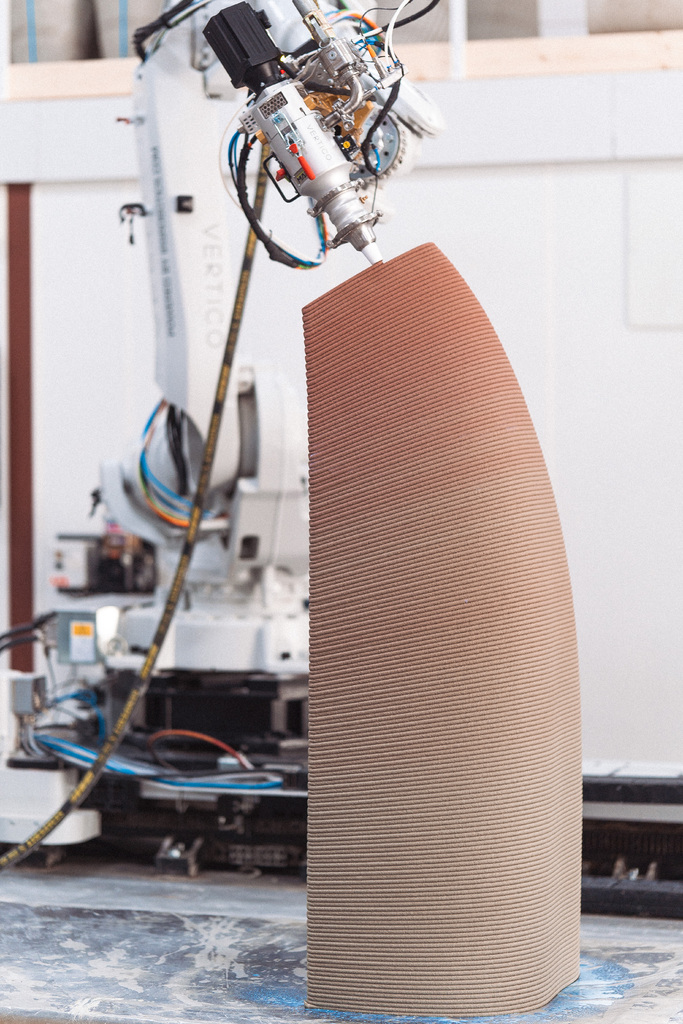

3D concrete printing takes a step closer to industrial standardization with the latest printhead developed by Vertico and Mai International. Combining Mai’s long-standing experience in mixing and pumping with Vertico’s expertise in robotic 3D printing has resulted in a hardware and software solution.

Both Mai and Vertico entered the concrete printing market early. Vertico’s expertise lies in robotics, software and 3D printing concrete, whereas Mai has deep knowledge of mixing and pumping coupled with engineering excellence. After a fruitful partnership, both parties agreed to combine their experience and expertise into one printhead, with the new patented Accelerator Printhead Solution as a result.

“The timing and circumstances of our collaboration were ideal. The complimentary areas of expertise and matching vision’s concerning the development of the concrete printing market meant that we could make the most of the potential.”

– Hannes Papousek, CEO, Mai International

Features

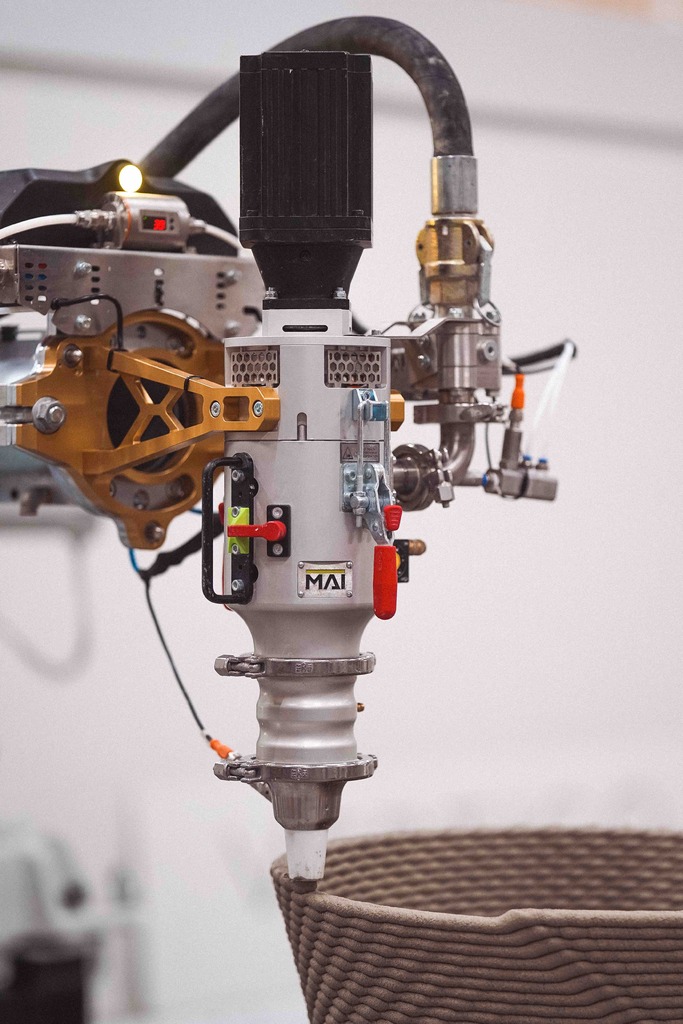

The Accelerator Printhead Solution boasts a very high mixing quality. The deformations often seen with other solutions are a thing of the past. Blockages of the accelerator inlet are minimized if not eliminated with the pulsation free injection. Another remarkable upgrade is in the cleaning: with removable counter pins and a patented lining solution, the printhead is close to self-cleaning with minimal disassembly required.

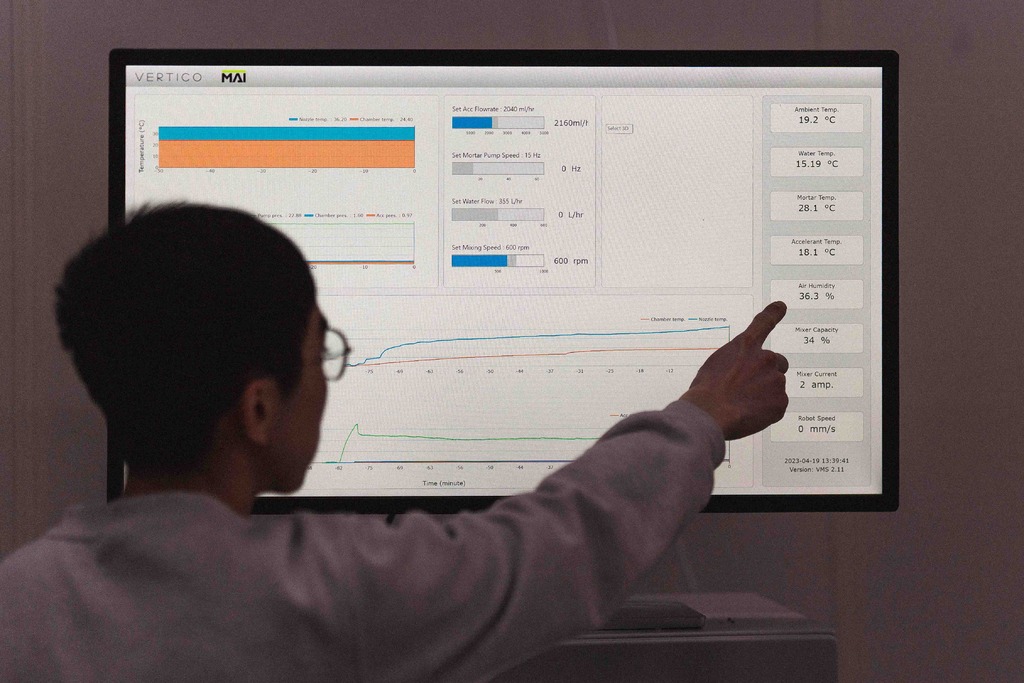

The solution also comes with a 1K printhead for standard concrete printing, and the quick-change device makes the switch easy. The full solution features multiple in-line pressure and temperature sensors and also measures air humidity, accelerant flow rate, motor torque and much more. All this information is monitored live in order to take timely action. This way you can keep track of your print in real time.

The Monitoring Software displays the key metrics and print settings over time. This information is crucial for a successful print.

Centralized control

For an industrial setting reliability and control are essential. In addition to the many features and high quality, the full system can be controlled by a centralized touch-screen Human Machine Interface (HMI). This user-friendly system, in combination with the monitoring, incorporates all of Vertico’s printing experience. From a startup procedure checklist, to direct setting changes, warnings and monitoring all in one place.

“Like with any new technology it is crucial to understand what is happing in real time. With our year of experience, we know what to look out for and pride ourselves in good user experience with monitoring and control.”

– Volker Ruitinga, CEO, Vertico

Continuing partnership

This new venture is just the beginning. Together Mai and Vertico continue to push the technology to the next level. With new add-on’s to the printhead already under development including a pinch valve, rotating nozzle and color addition.

www.mai.at

www.vertico.xyz