Milan's historic Affori neighborhood has been undergoing redevelopment since 2016. In this context, new residential complexes are being built in the immediate vicinity of the adjacent metro stations, filling the neighborhood with life again. Residents benefit from the sustainable advantages of Xella products.

High-performance, sound-insulating, and fire-resistant – these are important properties in the construction of apartment buildings. And these standards were not only the driving force in the redevelopment of Affori, Milan’s historic districts. The Standards ensure the safety of the people who live there and are the highest priority during construction.

These properties and standards convinced the construction company SILE Costruzioni Srl, based in the province of Bergamo, to use Xella products for the residential project in Affori.

The project involves the construction of several residential buildings, divided into three lots. The first lot was completed in 2018. In September 2021, work began on the second lot for a total of 178 Class A apartments with corresponding garages and basements. It should be finished until the end of the year.

Sustainable and insulating with Ytong building systems

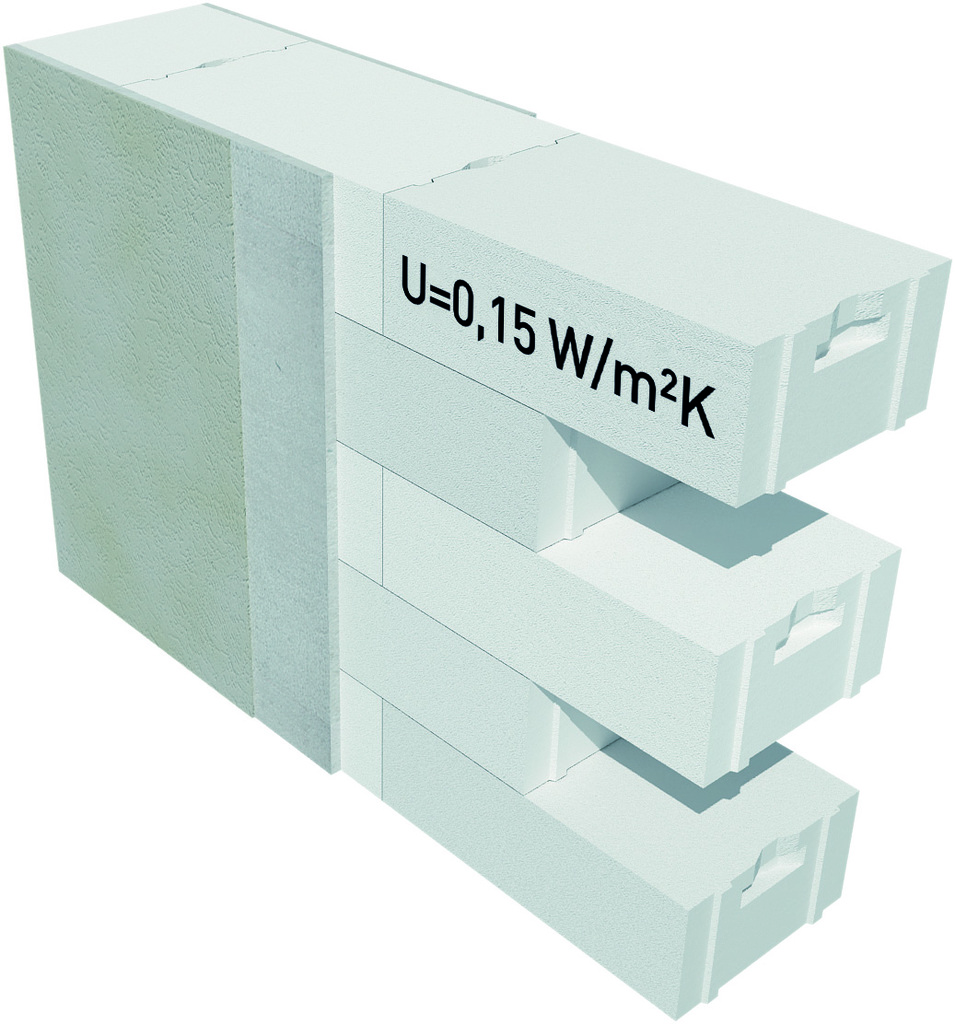

The construction low weight leads to a reducing load on the supporting structure. For this reason, Ytong Climagold blocks were used, each 30 and 40 cm thick. With only 300 kg/m³ nominal density and a dry thermal conductivity of 0.072 W/mK, respectively thermal resistance of 0,15 W/m2K, the block guarantees exceptional performance for a single-layer wall. The special feature: Despite their low thickness, they are thermally insulating, sound-insulating, and fire-resistant and ensure a simple, quick, and economical installation. In the first block 2,000 cubic meters of blocks were used for the external walls. In the second block 3,000 cubic meters Ytong blocks were used.

As far as the mortar for laying the bricks is concerned, Ytong FIX N200 was chosen.

The Multipor M3 mineral insulation boards, on the other hand, were used to correct the thermal bridge. Heat thus remains in the rooms and does not escape to the outside through the outer facade. This saves residents heating costs during the cold season. For bonding the boards, Multipor FIX X700 was selected.

Saving labor work with modern construction

The construction method involves single-layer masonry with Ytong blocks and the use of specific mortars and plasters: using products with the same properties guarantees a unique behavior of the materials, uniform in performance, ensuring high quality results for efficient, long-lasting, and safe constructions in every situation. Furthermore, the modularity and the perfect complementarity of the Ytong system allows you to design and build quickly and easily. Complete system also means a single supplier and a single interlocutor to turn to, also for the benefit of logistics management and on-site support.

As a result, project costs were reduced. The single-layer masonry allows to build the masonry faster than the traditional system with brick and insulating coat, because it allows to avoid the laying phase of the insulating material. The building material is usable in such a way that no external aids were necessary.

Transportation of materials was kept short. The material is supplied from the nearest depots to optimize transport times and costs. This benefits the environment and reduces CO2 emissions. At the same time, Xella thus supports local suppliers.

The Ytong building system was used by the construction company S.I.L.E for other projects. These were not only residential complexes, but also commercial buildings that must meet further and higher standards.