A small pavilion of 29 m² will function as a caretaker’s lodge in the heart of Harfleur, in between 180 social housing units. La Sphère, printed and developed by CyBe Construction on behalf of Bouygues Bâtiment Grand Ouest, Immobilière Basse Seine, and Archétude.

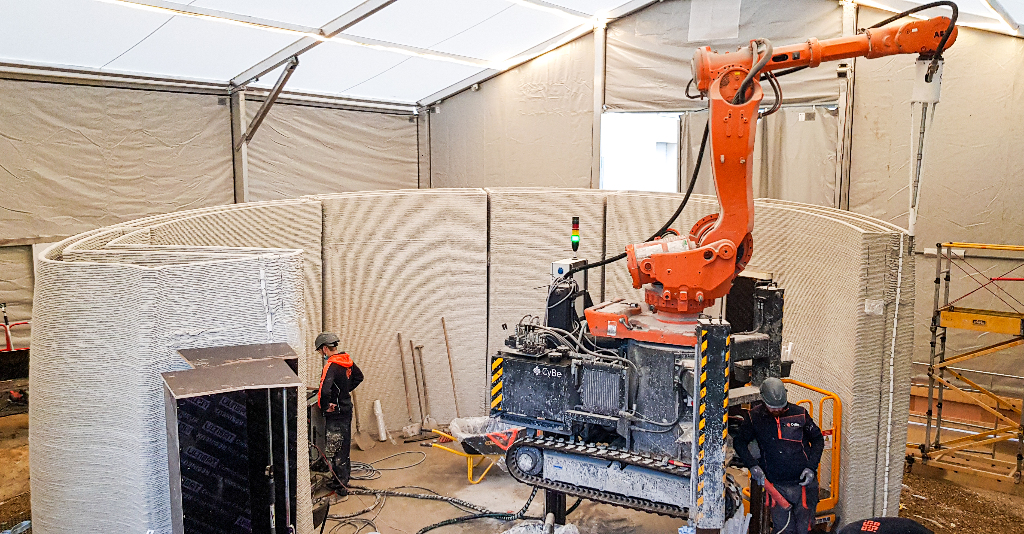

Normandy’s first 3D printed guard house is located in Harfleur, in Seine-Maritime (France). La Sphère consists of 11 printed elements, printed in 21 hours. All of these elements are printed on location, by using CyBe’s Mobile RC 3Dp. The guard house is the result of the printing experience using the innovative process developed by CyBe and will be used for the caretaker.

“I am extremely proud, and the process is groundbreaking. The advantages: first of all, the 3D printer carries out one of the most painstaking tasks on the whole site”, says Bruno Linéatte, Director of R&D Building Methods at Bouygues Construction. “This allows us to create complex architectural shapes, at a very competitive rate, keeping absolute control. And finally, this technique means we use less materials in exactly the right place. I worked out the figures with the CyBe teams. Here, we've used approximately one third less concrete compared to amounts used in the traditional method. The huge advantage is the freedom it gives us.”

The mobile CyBe 3Dprinter directly printed the concrete walls on-site in different successive layers. The walls are composed of several cavities which contain the insulation and a chaining structure. The walls are made of 11 independent vertical elements up to 2.5 m wide and up to 3.3 m high.

A new step in the development of the construction of tomorrow. This project illustrates the major breakthrough in 3D printing techniques and their change of scale applied to the construction sector. It also highlights the prospects that these technologies can offer for building simpler and more sustainably. La Sphère aims to strengthen the architectural quality of buildings, improve the comfort of residents and guarantee a 40% reduction in energy consumption for the residence for 15 years.

Watch a video about the project here: